In recent years, water and wastewater project owners, engineers, and contractors have been increasingly turning away from legacy procurement models like design‑bid‑build (DBB), instead choosing collaborative delivery methods such as progressive design‑build (PDB) or construction management at-risk (CMAR). These models promise greater speed, improved risk management, and stronger collaboration. Yet the difference between promise and performance often hinges on how well everyone understands what’s coming when and who is responsible.

Collaborative delivery methods promise faster schedules, broader stakeholder input, and early alignment on cost and constructability. However, these benefits are easily compromised. Accelerated timelines falter when decision points aren’t clearly defined or when approvals stall. Broader collaboration loses effectiveness without clear roles, leading to confusion and underrepresentation. And early alignment on scope, budget, and constructability breaks down when preconstruction drifts due to vague responsibilities or deferred decisions, eroding the value these methods are designed to provide.

If the benefits are so great, why is it that some projects using collaborative delivery methods struggle to deliver on those promises and instead fall short, resulting in delays, cost overruns, missed opportunities for O&M input, and frustration among stakeholders? While there are often compounding factors, many of those problems can be traced back to unclear expectations, poorly defined decision points, or lack of communication. Success depends not only on choosing the “right” delivery method, but also on making sure it’s transparent—especially in defining what happens when and who is responsible for taking action.

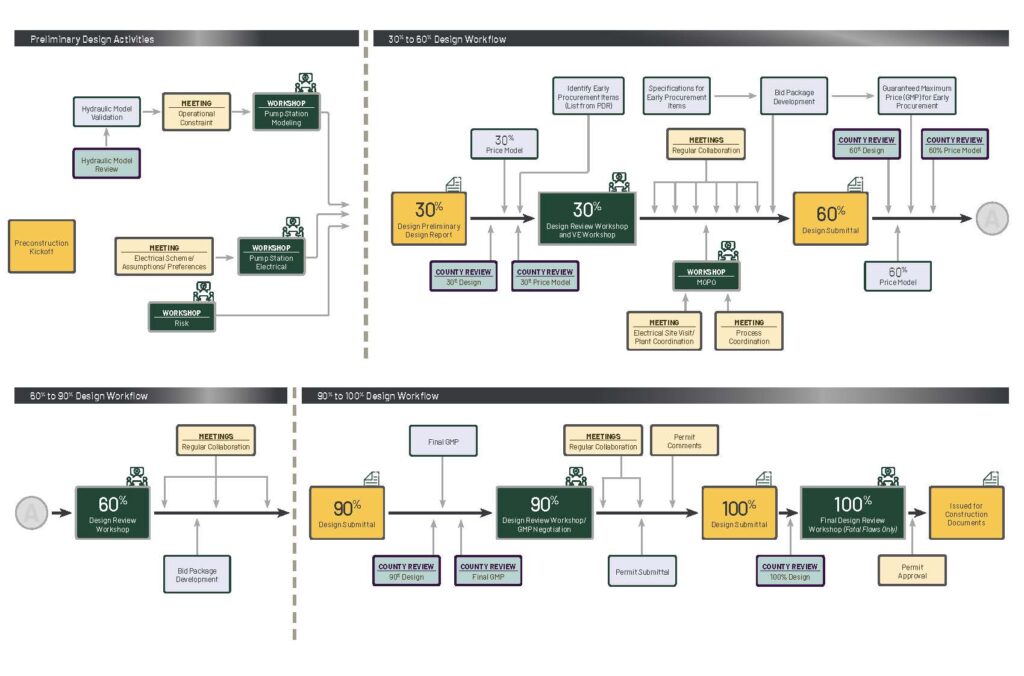

That’s where communication tools like a project flow diagram can be implemented to distill a complex process and set of expectations into a simplified visual tool that can be shared and understood by all project stakeholders. The flow diagram can take many forms but is designed to incorporate key meetings, workshops, design decision points, and major deliverables. A corresponding legend can be developed in conjunction with the flow diagram to identify key decision points and required decision-makers that need to be present. With everyone aligned on decision points, responsibilities, and timing, expectations are set clearly from the start, minimizing missteps downstream.

Unlike a Gantt chart or CPM schedule, a flow diagram provides a simplified visual roadmap of the preconstruction—and overall project—life cycle. It shows how the work will progress, who needs to be involved at each phase, and where critical decisions occur. This clarity ensures that the right people are at the table at the right time—with authority to act.

Importantly, the flow diagram isn’t a substitute for a detailed schedule; it’s a complement. It helps align team members who may not be familiar with technical scheduling tools and provides owners, designers, contractors, and operators with a shared reference point throughout delivery.

To be most effective, flow diagrams should follow the principles outlined in WCDA’s best practices, including the Water and Wastewater Collaborative Delivery Handbook and both the PDB and CMAR Procurement Guides. These resources emphasize the importance of early and ongoing communication, role clarity, and active stakeholder engagement.

Collaborative delivery isn’t automatic; it requires preparation, ownership, and continuous alignment. A well-designed project flow diagram is a simple but powerful step toward making the process visible, understandable, and, ultimately, successful.

What will your team do to make the path forward clearer?