Challenge

The Tomahawk Creek Wastewater Treatment Facility Expansion was a direct response to the facility’s aging infrastructure and more stringent effluent limits, as well as treating the increased flow from population in surrounding communities previously treated outside of the service area. Up until the expansion, Johnson County was sending 60% of the wastewater in the Tomahawk service area to Kansas City, MO, which was costing the County millions of dollars annually.

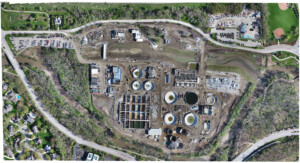

Over the course of the Tomahawk expansion, the entire project team encountered complex challenges and instituted innovative solutions while remaining on schedule and on budget. The expansion was the largest project ever undertaken by Johnson County, growing the facility’s footprint by approximately 30%. The overall facility improvements included new influent pumping and coarse screening, five-stage biological nutrient removal treatment, intermediate pumping, disinfection, tertiary filtration, solids processing and more. With this came the challenge of incorporating existing buildings into new construction, rehabilitating existing facilities, running miles of underground utilities, and major earthwork that included raising the site out of the flood plain.

One challenge was the development of the auxiliary wet weather treatment facility, now the largest facility in the world to use cloth disk filter technology. This installation, which incorporates eight disk filter cells that each contain 24 disks, was performed in extremely tight space constraints and required the construction team to balance the sequencing and coordination of numerous trade partners involved in building the pump houses. The disk filter facility’s capacity is 115 mgd; when combined with the traditional process, it allows the Tomahawk plant to accommodate flows up to 172 mgd.

Communication was key throughout this complex disk installation process. To complete it, the project team engaged superintendents with applicable experience, built out detailed work plans for each process, collaborated closely with the design team and trade partners, and had inspectors on site at all times.

The facility site is located at the confluence of two major creeks: Indian and Tomahawk. To avoid the existing flood plain that ran right through the project site, major earthwork had to be conducted to elevate the project site. The McCarthy team utilized in-house XS10 dot cloud scanning equipment to determine the cuts and fills to optimize the soil available and maximize fills in the appropriate sequence. The project team utilized allowances set aside for mitigating unsuitable soil risks to stay on schedule and the allowance was also used where the bedrock elevations differed from design assumptions based on the geotechnical report findings. Because of the floodplain and groundwater elevations, the design included 792 drilled shafts to support new structures. The project team determined early in design to divert all flow during construction to Kansas City, MO, to eliminate extensive maintenance of plant operations (MOPO) and shorten the duration of construction by an estimated 1.5 to 2 years.

One final challenge that the entire project team faced right out of the gate during design was an initial cost estimate that was $60 million over Johnson County’s budget. Using the CMAR delivery method and having everyone come together to develop innovative cost-saving options, the team was able to conduct a thorough value engineering review and accelerate redesign changes in just six weeks to keep the project on schedule and on budget for construction groundbreaking in early Q2 of 2018.

Approach

Johnson County, with prime consultant Black & Veatch teamed with HDR for engineering services, selected the CMAR delivery method to find a qualified contractor that could best support the design phase with value engineering and constructability review as well as develop cost and schedule certainty. McCarthy Building Companies, Inc. was selected as the CMAR for the project. The team demonstrated the in-sync movement by the group early on and earned buy-in from all parties to help ease the early unknowns and concerns.

Results

The expansion and improvements of this facility—which featured 30 new structures, more than 130 installed pumps, 50,000 cubic yards of concrete, 9 miles of underground utilities, and 792 deep foundation drilled shafts—made an immediate impact for Johnson County and the community with expanded wastewater treatment from an annual average of 7 mgd to 19 mgd during dry weather and up to 172 mgd during wet weather. It will also help reduce future expenses for Johnson County by an estimated $785 million over the next 35 years when compared to a 10 mgd treatment option that would have continued to send a portion of the flow to a neighboring utility for treatment. The project team also hit their first milestone two months early and the facility was able to treat its own liquid waste sooner than anticipated.

From a local impact standpoint, 350 local construction professionals were on site at the peak of the project with 82% of subcontracted work and 90% of the labor craft workforce coming from the local community. Additionally, over $16 million of work was provided to DBE/MBE/WBE trade partners throughout the course of the project.

Other WCDA members involved: Core & Main (supplier of pipes, valves, fittings); Tnemec (supplier of high-performance protective coatings)

“The Tomahawk Creek Expansion was the largest capital project ever undertaken in Johnson County’s history. There were many critical considerations for us, including ongoing operational costs, a major rehabilitation of an existing facility, and overall project schedule. These factors led us to select construction management at-risk as the preferred delivery method. The collaborative team of JCW, McCarthy, Black & Veatch, and HDR allowed us to effectively navigate those potential hurdles and provide value-driven constructability input, project cost certainty, and transparent risk management. This project was completed ahead of schedule and on budget. Based on those successes, we’ve elected to use the method once again for our next large project, the Nelson Complex Improvement Project.”

– Susan Pekarek, General Manager, Johnson County Wastewater