Challenge

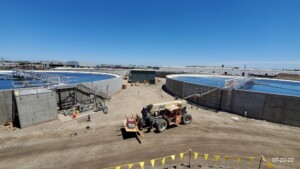

The Stockton Regional Wastewater Control Facility (RWCF) occupies approximately 690 acres adjacent to the San Joaquin River. The RWCF was first constructed in 1922 and was the primary treatment facility servicing businesses and residents in Stockton, CA. The RWCF was incrementally expanded to accommodate growth. In 2011, the Stockton City Council approved the Capital Improvement and Energy Management Plan (CIEMP) that provided a strategy for planning and implementing improvement projects for the RWCF. Since that time, the City has advanced the design for a new headworks facility and other minor ancillary projects identified in Phase I of the CIEMP. In June of 2014, the City was issued a new National Pollution Discharge Elimination System (NPDES) permit that sets forth the treatment requirements for the next five-year permit cycle and includes 10-year compliance for nitrate + nitrite limit. The CIEMP alluded to the possibility of enhanced secondary treatment to remove nutrients, but did not specify the facilities needed to meet possible limits into the future. Also, the City is under a time schedule order (TSO) to meet strict disinfection by-products limits on total trihalomethanes. To advance the effort to meet the TSO, the City completed a basis-of-design report for the tertiary plant projects which included upgrades to the dissolved air flotation (DAF) system and a new ultraviolet light (UV) disinfection facility.

With budget constraints and a plethora of existing problems and possible solutions, the principal challenge for the City and its selected design-builder was to sort through existing needs, determine best-value solutions, and develop a significantly more cost-effective approach for project implementation so that competing needs and priorities could be adequately reconciled. Key for this project was: Will growth accelerate to pre-2010 rates as the CIEMP assumes, or will growth continue at the current, more measured pace?

Approach

The design-build (DB) team of AECOM and W. M. Lyles JV closely reviewed the CIEMP preliminary designs for the headworks and tertiary treatment. Based on observations from the initial review of performance data and historical drawings, the DB team outlined the below key elements of a recommended approach:

- Revised Design Criteria and Staged Implementation Plan. Although the DB team planned to conduct a thorough study during Phase 1 engineering, it was optimistic that a staged approach and implementing the 60% capacity increases outlined in the CIEMP in two or three stages would result in significant savings for the City from deferring investment to only when it is needed.

- Abandon Obsolete Facilities. Due to a combination of age, process obsolescence, and energy inefficiency, a number of existing processes were candidates to be fully replaced with modernized facilities. This included existing headworks, biotowers, secondary clarifiers, secondary effluent pump station No. 1, nitrifying biotowers, DAFs, and tertiary filters.

- Add New Core Treatment Processes. To position the Stockton plant for its next 50 years of operation, more modern and energy efficient unit processes were recommended to best meet current and anticipated future regulatory requirements while minimizing life cycle costs. Proposed new core processes included a modernized headworks, BNR activated sludge, disk filtration, UV disinfection, and centrifuge dewatering.

- Water Conservation. RWCF flow records showed an average difference between influent and effluent flows was as much as 8 mgd. This implied that seepage and evaporative losses of water across the approximately 700 acres of ponds and wetlands were resulting in a significant loss of water to the delta. To add some perspective, 8 mgd represents the water consumption of a good-sized city. Thus, bypassing the ponds during normal operations while sending a small flow to preserve the wetlands would have the benefit of enhancing water conservation by returning significantly more flow to the river.

- Repurpose Existing Structures. To obtain continuing value for the City’s past investment, existing structures could be modified and repurposed to contribute to a simplified process flow scheme. Examples included: converting the existing biotower pump station to a new secondary effluent pump station; altering the existing gravity thickener for use as centrate equalization tank; changing secondary effluent pump station No. 2 to serve as a bypass/peak-flow pump station; and repurposing the oxidation ponds (one or all) to serve as emergency flow diversion/storage.

- Make Personnel Facility Improvements. A modern plant needs the support of a skillful workforce. The DB team proposed to provide modern facilities to promote maximum efficiency for plant staff.

Results

The work included development and preparation of all design documents and construction of the project, including construction administration and management services in two phases. Phase 1 of the work consisted of the initial design of the project and negotiation of the Phase 2 contract price and time. Phase 2 of the work consisted of the final design and construction of the project. Phasing of the overall construction (Phase 2) was also divided into two major pieces, the first being an interim expansion which is about halfway to the CIEMP recommended design loads for 2035, with a second step that would follow if triggered by increasing flows and loads to complete ultimate expansion to 2035 projected design loads. Sequencing of both equipment and structures was included in the scope of work for each expansion phase. Based on the deferred equipment and structures, the DB team estimated a deferred savings of approximately $25 million with this phased expansion approach.

In addition to all the capital benefits to the City of Stockton, these concepts also provided many other benefits, such as lower investment, lower operational costs, preserving wetland biodiversity, enhancing operations, meeting schedule, and maintaining flexibility for the future.

- Lower Operational Costs. Taking the DAF out of normal operation reduced polymer consumption by millions of pounds per year. Eliminating chlorination, dechlorination, chloramination, and substituting new UV disinfection also significantly reduced RWCF chemical usage. The new UV disinfection increased power consumption, but this was offset by savings in chemical. Overall, life cycle costs at the RWCF were significantly reduced.

- Preserving Wetland Biodiversity. The Stockton wetlands are a known breeding site for birds and are enjoyed by hundreds of bird watchers every year. A recent survey by the Audubon Society found some 55 species and 7,500 birds. While the DB team proposed taking the wetlands out of the normal treatment process, it ultimately preserved this significant public amenity by a one-way diversion of sufficient flow to keep the wetlands green.

- Minimizing Capital Costs and Maximizing Best Value. The DB team prepared sketches of proposed improvements. It obtained equipment pricing from its suppliers and from recent projects and the estimating team prepared cost estimates for each work area based on these concept designs. The team forecasted significant savings over the engineer’s estimates furnished by MUD’s various consultants. Perhaps the two most important attributes of approach were the ability to (1) meet the new regulatory requirements, and (2) stay within budget.

- Further Improvements to Operational Efficiency. AECOM/WML believed a priority for the current project was to improve the current operations, specifically by providing the following:

o A new central control room for all facility operations

o New office space for engineering, operations, and the city management staff

o Relocate the laboratory functions into a new laboratory space, which includes space for the environmental group

o Remodel and code updates to all control rooms, lockers, and shower areas

o Enhancements to the existing administration building to include space for city management and site safety operations

o Enlarging the operations support offices into the area now used by the environmental group

- Future Flexibility. One key feature of a treatment plant design is its ability to both anticipate and accommodate future regulatory changes. This requires an ability to be flexible and to morph to meet future requirements with minimal investment. Given the magnitude of the City’s current spending to achieve current regulatory limits and expand the plant to meet forecast capacity requirements, building in allowances for future requirements was a reasonable policy goal. As the DB team’s goal was to support the City with these upfront planning efforts, it identified a number of options for future plant modifications should regulatory requirements change in the future. For example, one recommendation was to provide deep tank aeration as a future building block. This unit process has an inherent capability to be modified for increased nitrogen removal. Other examples of flexibility included meeting a future effluent requirement for phosphorus—which could be accomplished by removing phosphorus using the currently practiced chemically enhanced primary clarification. Another example would be to modify the aeration basins to add biological phosphorus removal.

Other WCDA members involved: Tesco Controls (design-assist subcontractor); Core & Main (supplier of pipes and fittings); Tnemec (supplier of high-performance protective coatings)

“The City of Stockton’s $219 million progressive design-build 55 mgd Regional Waste Control Facility Modifications Project experienced significant budget challenges during Phase 1 design and preconstruction services. The AECOM-Lyles team has shown an exceptional degree of collaboration and innovation partnering with the City of Stockton to overcome these challenges, even altering the lump-sum contractual approach to a GMP with contingency sharing to achieve a mutually acceptable budget and schedule path to advance the project . . . experiencing meaningful cooperative dialogue between the owner and design-builder exhibiting a ‘project first’ mentality . . .”

— Art O’Brien, PE, Project Manager, City of Stockton